Magnetic Stirrer System

| 2300*1350*1180 mm (Depending on the capacity of the furnace) | Appearance size |

| Depending on the capacity of the furnace | Power |

| 10-40ton | Capacity |

| 600mm | Adjustable Height |

| 3000mm | Walking track |

| 6500Gs | Magnetic field strengh |

| ≥ 10years | Lifetime of the permanent magnet |

| ≤ 700mm | Liquid aluminum depth |

| ≤ 50 °(can be adjusted) | Suitable environment temperature |

| ≥ 600Gs (250 mm away from the cover) | Magnetic induction density |

| 0-250r/min (can be adjusted) | Rotation speed of the center aluminum liquid |

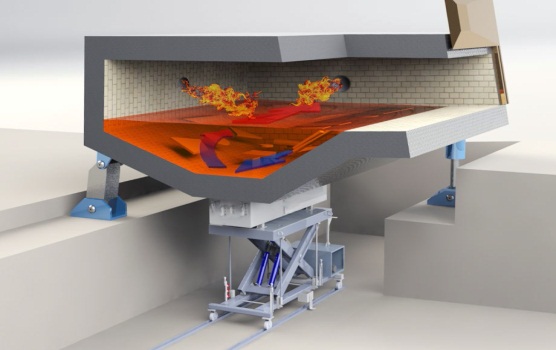

Stirrer is an advanced and unique system for creating powerful and controlled magnetic fields. This device sends very strong and controlled magnetic fields into the furnace and moves the melt inside the furnace in a vortex. This system can be placed at different defined stations under furnaces And do homogenization; Also, the amount of magnetic field entering the furnace can be controlled. The non-magnetic nature of aluminum and the movement under this magnetic field is one of the remarkable points of this product. By creating this flow inside the melt, the oxidation of the melt, which is one of the problems of the aluminum smelting process, is drastically reduced and practically very little slag is produced. The melt flow causes the temperature to be uniform in different parts of the melt and helps to reduce oxidation. The flow of the melt causes the key metals to spread evenly inside the melt, bringing about the uniformity of the chemical composition. The movement of the melt causes the gas mounds and inclusions trapped inside the underlying layers of the melt to form slag and the resulting ingot is free of impurities; This advantage makes it possible to produce extrusion billets directly from smelting waste

Low maintenance costs –

Elimination of temperature difference of aluminum melt up to 5 degrees Celsius

Increase melting efficiency 16-13% –

Durable for long-term operation –

Ability to install online data monitoring system for product warranty

Installation, commissioning and dedicated training –

In the aluminum alloy industry, homogenization of melt containing different alloys and uniformity of melt composition is of special importance and this issue is not hidden from any of the actors in this field. This issue is so important that not paying attention to the uniformity of the chemical composition of the melt and ultimately the chemical composition of the resulting parts can lead to irreparable consequences in the industries that consume these parts. Aluminum alloy used in parts must be structurally free from defects under working conditions. Most of the structural defects of the parts are related to the process of melting, alloying and casting, and this issue further highlights the importance of controlling and paying attention to this process. Lack of use of stirrer and non-uniformity of chemical composition causes non-uniformity of microscopic structure of parts in different parts. Despite these uniformities and differences in yield stress and fracture stress in different parts areas, parts are under the working conditions of the stress focus area or suffer from metal fatigue more quickly. The stress areas are the site of microscopic cracks, and cracks form and expand, eventually leading to critical failure when the crack reaches a critical size

Complete homogenization of the alloy composition –

Significant reduction in oxidation and soil production –

Significant increase in melting and casting speed –

Melt waste by dragging it into a molten vortex and save energy –

Low power consumption –

Air cooling –

This system is a basic need in all aluminum smelting industries, including alloying and casting industries of aluminum parts, billets and ingots, sheets and foils, profile making, ring making and radiator making also wire and cable, and can improve efficiency and Increase the quality of the product to be used